Glass Delamination Analysis

Schedule a MeetingGlass DelaminationAnalysis

Glass delamination can be identified as Separation of thin glass particles (lamellae) that shed from the internal surface of glass container. They appear as shiny, needle shaped crystals suspended in contact liquid product. Glass delamination is observed when glass-liquid interactions take place in which silica-rich layer poorly bonded to the substrate is the first stage for the initiation for delamination. In other words it is also known as leaching of ions into product.

Glass Delamination Testing

Leaching of ions from the inner surface of glass container into the product will significantly affects the product quality while compromising the durability of glass container. As glass delamination is a serious quality issue, recently many pharmaceutical products have been recalled due to glass delamination.

When small glass particles are injected to systemic circulation, it will lead to serious health issues. NRPL serves investigation and propensity studies. We follow general guidelines referred by various regulatory authorities including USFDA (USP General; information chapter <1660>, “Evaluation of the inner surface durability of glass containers”) and European pharmacopoeia (EP, Chapter 3.2.1)

Incidences of Delamination

- Thermal stress during vial formation.

- Processing vials during product filling.

- Interaction of glass with formulation.

- During storage.

Why delamination studies are required?

- Propensity (glass behavior) studies to evaluate glass delamination.

- Assessment of glass quality

- Pharmacopeial requirements to confirm the glass durability.

- To confirm glass composition as per the requirement.

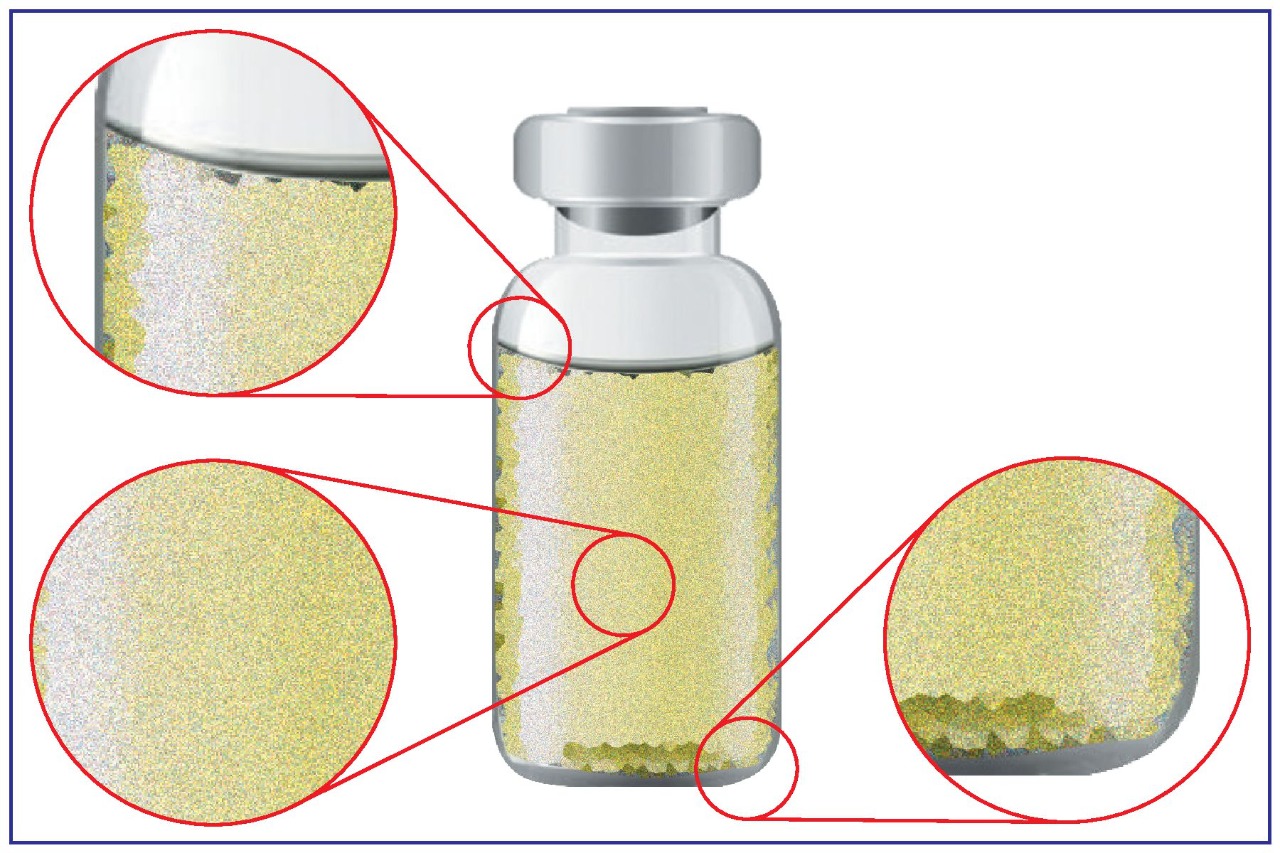

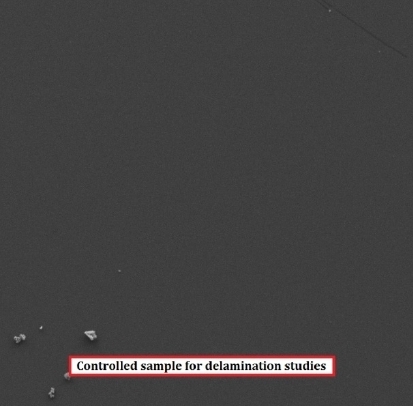

Difference between controlled and delaminated product packed in glass container (Illustration)

Sampling techniques for delamination testing

Nishka research has developed in house standard protocols for collection of samples. which are used in delamination analysis. These protocols will assure you that sample integrity and its internal structure is protected and will lead to trust worthy results.

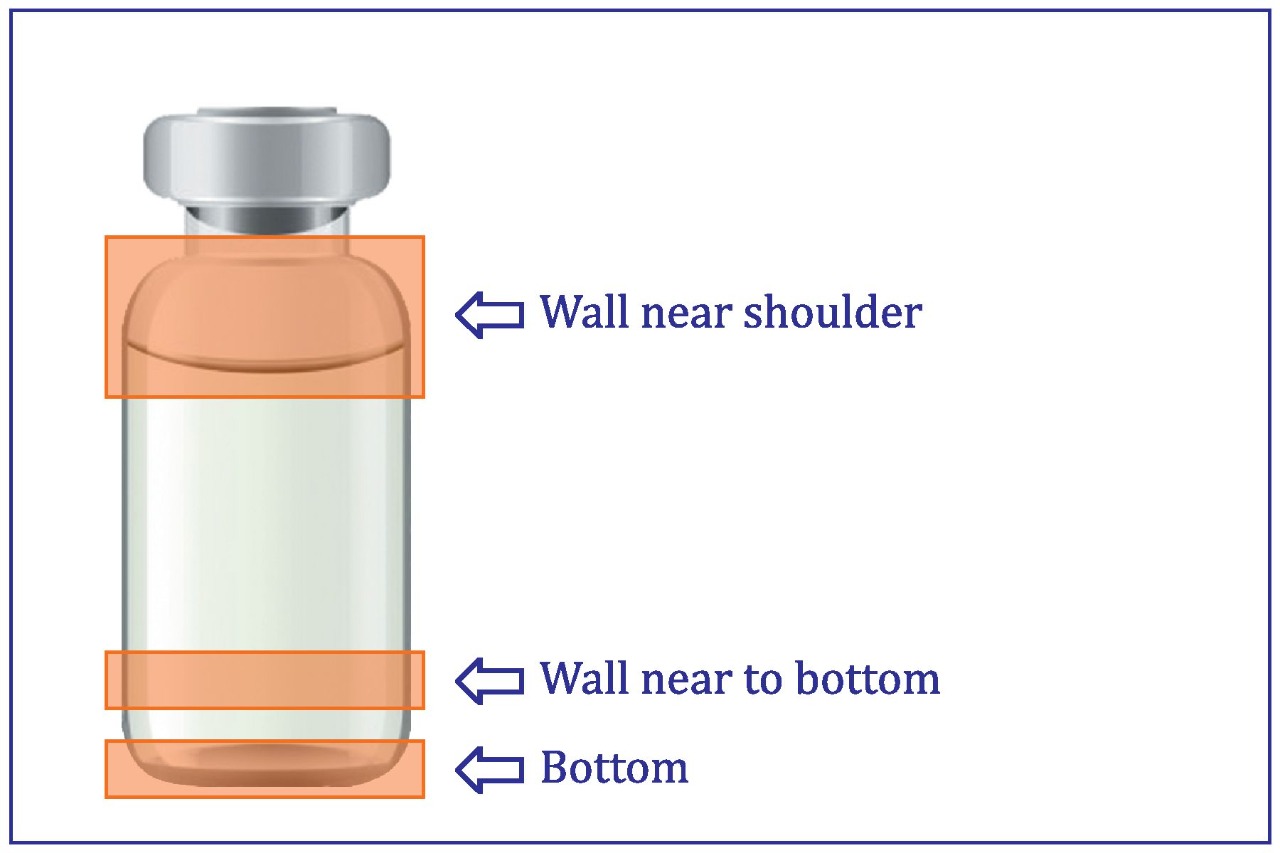

Location of sample to be collected from glass container for delamination studies

- Wall near shoulder

- Wall near to bottom

- Bottom

Why ChooseNishka Research

Most of the times companies are interested in performing delamination studies only when product is failed during stability studies (appearance of opalescence, Foreign particles and suspended particles). But the fact is delamination studies has to be performed as a part of product development and as a propensity studies.

Experts of NRPL will design appropriate protocols for evaluation of delamination studies. Delamination studies require multidisciplinary approach from early product development stage so as to avoid surprises post product development. Team of NRPL will synchronize with your team in designing the protocol for delamination studies.

If you require an expert advice for delamination testing, we are more than happy to assist.

Looking for a trusted partner to achieve your research goals? schedule a meeting with us, send us a request, or call us at +91 78427 98518 to learn more about our services and how we can support you.

Need help or have a question?

Nishka Research Brochure

We deliver next-gen research services, Testing & Consultation know more..