Microsection Analysis of ICs

Schedule a MeetingMicrosectionAnalysis of ICs

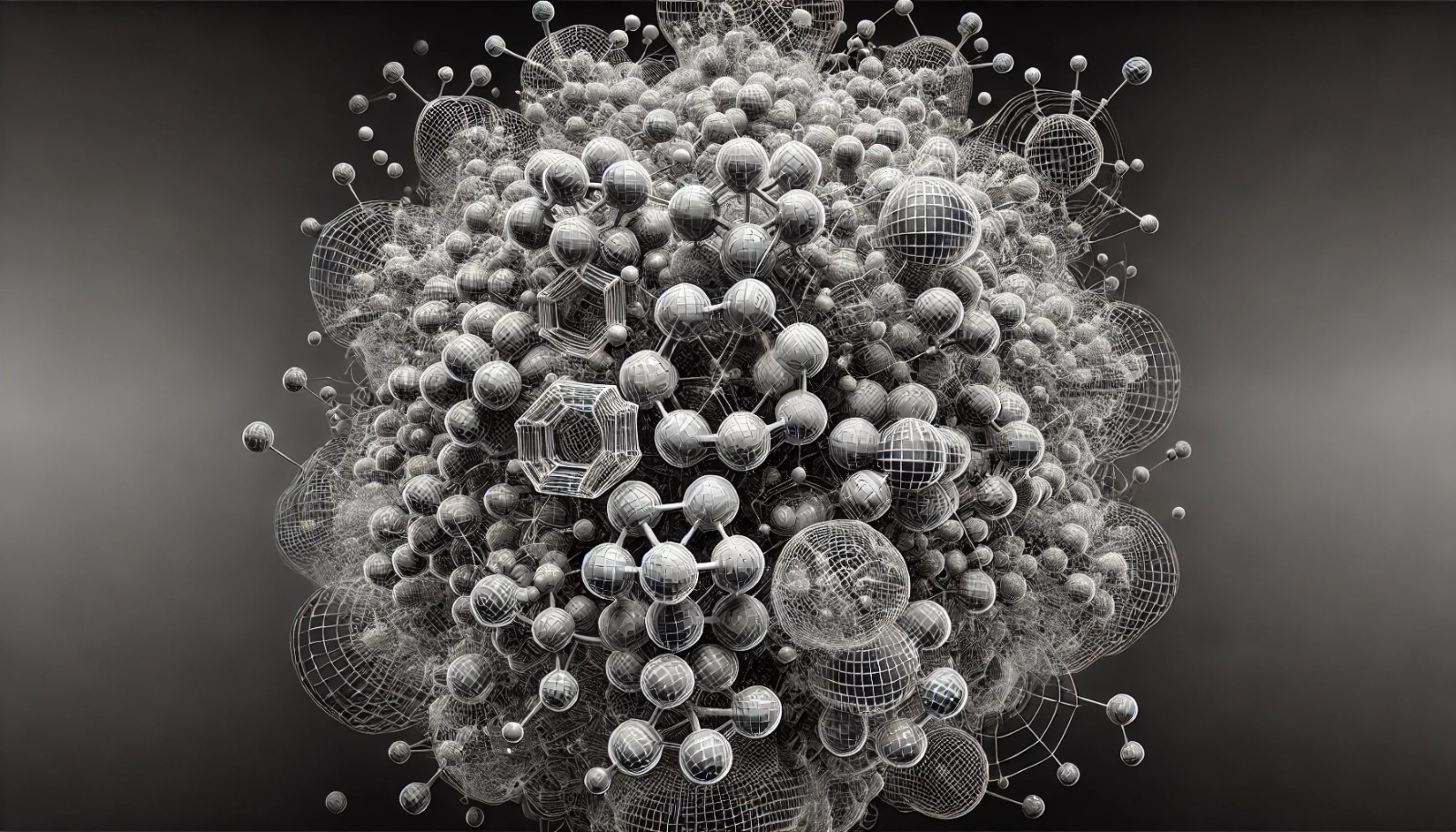

In electronics, Microsection analysis is most widely accepted for analyzing IC / PCB /PWB. It allows to visual inspection at the plane that cuts through the sample at nanometer-scale of microstructures and is destructive technique. They are commonly one for research, Failure analysis, Assurance of manufacturing quality, lot verification or vendor qualification. NRPL has the knowledge and experience to provide the highest quality services ad least turnaround time. Microsectioning of the electronic device / Sample can provide more details of quality of the manufacturing process, when coupled with elemental analysis techniques like SEM/EDS systems. The quality of the manufacturing process can be fully characterized and provide guidance for improvement of the manufacturing process.

Applications of Microsectioning

- PCB analysis

- Structural integrity analysis

- Coating thickness

- Chemical analysis

- Intermetallic layer measurements

- Cross sectional analysis

- Plating Thickness

- Number of layers in IC

Microsectioning is generally done for following

Microsectioning inspections: Microsectioning involves examining the connections of different electronic devices composed of different materials. Microsectioning is achieved majorly by grinding and polishing which various from sample to sample. Microsectioning is mainly dependent on hardness and ductility of the materials to grind, electronic components. Grinding parameters including rotation speed, pressure and time and abrasive material used will be optimized.

Electronic components: Visualizing the internal structures of the electronic devices by Microsectioning can reveal the issues associated with manufacturing and material quality. Microsectioning of IC ca reveals the die and its number of layers, die paddle an interconnections of wire bonds or solder bumps.

Solder connections: Polished microsections can be evaluated further for variety of analytical techniques. High resolution images will be captured using optical microscope or scanning electron microscope (SEM). Compositional / Chemical analysis can be performed with energy dispersive X-ray spectroscopy (EDS)

Why ChooseNishka Research

- Total quality assurance across all your processes

- Reduction of costs

- Minimization of safety and security risks

- Reliable testing for faster regulatory approvals of your products

- Ensuring the highest social accountability standards

Looking for a trusted partner to achieve your research goals? schedule a meeting with us, send us a request, or call us at +91 78427 98518 to learn more about our services and how we can support you.

Need help or have a question?

Nishka Research Brochure

We deliver next-gen research services, Testing & Consultation know more..