The company

A Gujarat based, leading manufacturer and supplier of Iron & Steel pipe products, fittings and accessories with manufacturing facilities in India, USA, Europe and UAE serving global needs. The company is involved in spiral pipes for the energy transportation sector; carbon, alloy and seamless pipes and tubes for industrial applications; and Ductile Iron (DI) pipes & Fittings for water and wastewater transportation.

The challenge

The FBE coating of the pipe has failed for unknown reasons. Exterior FBE coated pipes were observed with Loss of Adhesion of FBE coating at various parts of pipe.

Consultation requested to NRPL: We would request to investigate and identify the root cause/s and suggesting the remedies for failure of FBE coatings.

- Presence of any foreign contamination in submitted samples.

- Surface roughness of submitted samples.

The solution

NRPL is serving Various industries for more than 15 years, using its decades of experience in assessing Failure analysis using instrumental techniques like SEM (Scanning Electron Microscopy), EDX/EDS (Energy Dispersive X-Ray Spectroscopy), surface roughness (profile gauge and AFM), FTIR and DSC with highly qualified Experts. NRPL is serving, supporting and providing technical consultancy to various industries and research organisations based on established knowledge and experience.

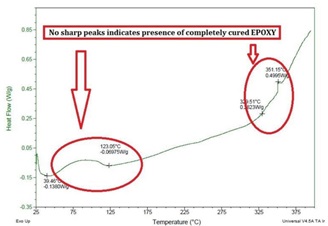

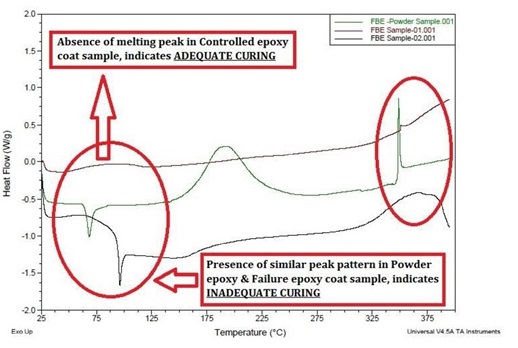

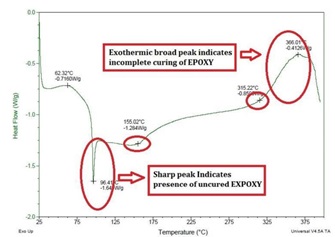

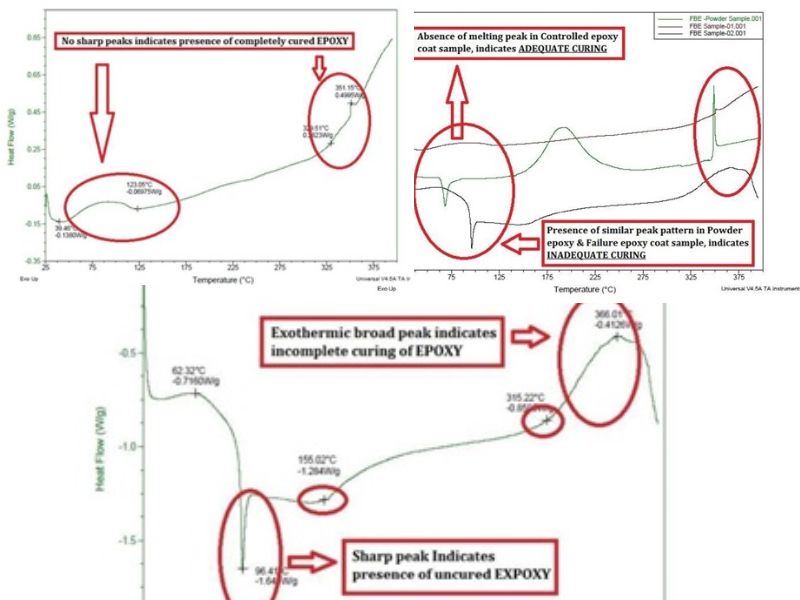

NRPL has taken the challenge, successfully investigated & identified the problem. We have performed DSC, FTIR, Surface Roughness, SEM (Scanning Electron Microscopy) & EDX/EDS (Energy Dispersive X-Ray Spectroscopy). We have observed the various differences in the cured FBE coatings of Failure and Control sample. We have also observed the changes in DSC thermographs of both samples (Failure and Control) hence forth we have concluded that INADEQUATE CURING of FBE

0 Comments