In the realm of pharmaceuticals, the safety and efficacy of the products are of paramount importance. Every aspect, from the active pharmaceutical ingredients (APIs) to the packaging materials, plays a crucial role in ensuring the product’s integrity. One such critical aspect that often goes unnoticed is the phenomenon of glass delamination. This process, although seemingly innocuous, can have significant implications on the quality and safety of pharmaceutical products.

Understanding Glass Delamination

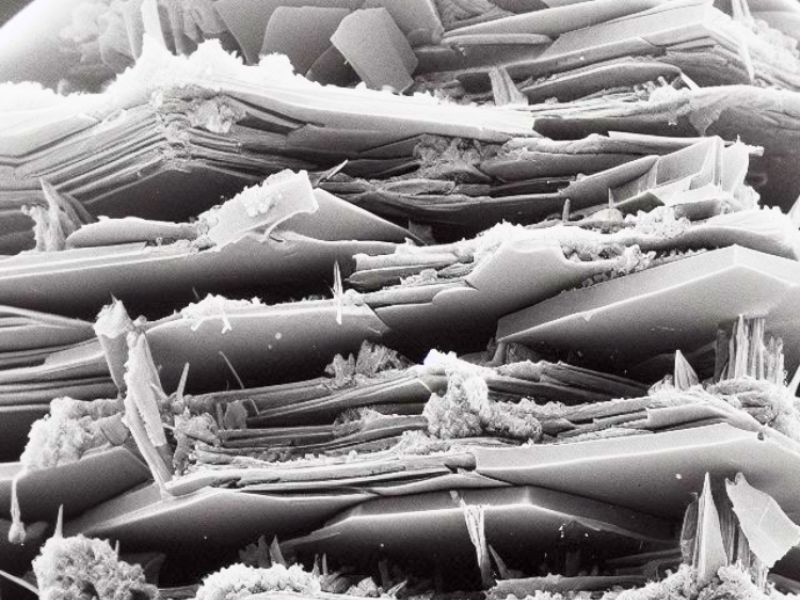

Glass delamination refers to the process where tiny glass flakes separate from the inner surface of glass containers, such as vials or syringes, and contaminate the pharmaceutical product contained within. This not only compromises the product’s quality but can also pose serious health risks if these glass flakes are administered to patients. Therefore, understanding and preventing glass delamination is a critical concern for pharmaceutical manufacturers worldwide.

Certain pharmaceutical products are more susceptible to glass delamination than others. These typically include products with a high pH, products that are stored for long periods, and products that undergo freeze-thaw cycles. The type of glass used can also influence the risk of delamination. For instance, type I glass, which is commonly used for injectable products, is known to be more prone to delamination than other types of glass.

Causes of Glass Delamination

The causes of glass delamination are multifaceted and can be traced back to both the glass manufacturing process and the pharmaceutical product itself. During the manufacturing process, factors such as the composition of the glass, the temperature at which it is formed, and the cooling rate can all influence the glass’s propensity to delaminate.

On the other hand, the pharmaceutical product can also contribute to delamination. For instance, certain chemicals in the product can react with the glass, causing it to weaken and eventually delaminate. Similarly, the storage conditions, such as temperature and humidity, can also affect the risk of delamination.

Glass Delamination Studies at Nishka Research

At Nishka Research, we specialize in conducting comprehensive glass delamination studies. Our state-of-the-art facilities, equipped with advanced analytical instruments like scanning electron microscopy (SEM), allow us to accurately identify and measure glass delamination. Our team of experienced scientists and researchers apply their in-depth knowledge of pharmaceutical sciences and analytical techniques to interpret the results and provide actionable insights.

Our approach to glass delamination studies is client-centric. We understand that each pharmaceutical product is unique, and therefore, the approach to studying its risk of glass delamination should be tailored to its specific characteristics. We work closely with our clients to understand their product and design a study that will provide the most relevant and useful results.

Case Studies

Over the years, we have conducted glass delamination studies for a wide range of pharmaceutical products. One such case involved a pharmaceutical company that was experiencing recurring instances of glass delamination in their injectable product. Our team conducted a comprehensive study, examining the glass vials, the product, and the storage conditions. Through our study, we were able to identify the cause of the delamination and recommend changes to the company’s manufacturing and storage processes. As a result, the company was able to significantly reduce the instances of glass delamination in their product.

The Future of Glass Delamination Studies

The field of glass delamination studies is continually evolving, with new advancements and techniques being developed regularly. At Nishka Research, we are committed to staying at the forefront of these advancements. We continually update our methodologies and equipment to ensure that we are providing the most accurate and relevant results to our clients.

The Importance of Glass Delamination Studies

The implications of glass delamination are far-reaching. Beyond the immediate risk to patient safety, glass delamination can lead to product recalls, regulatory scrutiny, and damage to a company’s reputation. Therefore, conducting glass delamination studies is not just about ensuring product safety; it’s also about safeguarding the company’s brand and market position.

The Nishka Research Approach

At Nishka Research, we believe in a proactive approach to glass delamination. Instead of waiting for delamination to occur and then reacting, we help our clients anticipate and prevent delamination. Our studies are designed to identify the risk factors for delamination in each specific product and provide recommendations on how to mitigate these risks.

Our approach is based on a deep understanding of both the glass manufacturing process and the pharmaceutical product. We consider factors such as the type of glass used, the product’s chemical composition, and the storage conditions. Our comprehensive studies provide a complete picture of the risk of glass delamination, allowing our clients to make informed decisions about their product and packaging.

Our Expertise

Our team of scientists, engineers, and researchers is our greatest asset. With their in-depth knowledge of pharmaceutical sciences, analytical techniques, and regulatory requirements, they are able to deliver innovative solutions and personalized support to our clients. Their expertise is backed by our state-of-the-art facilities, which feature advanced analytical instruments like high-performance liquid chromatography (HPLC), gas chromatography-mass spectrometry (GC-MS), scanning electron microscopy (SEM), Energy Dispersive X-Ray Analysis (EDAX) and Inductively Coupled Plasma Optical Emission spectroscopy (ICP-OES).

Partnering with Nishka Research

When you partner with Nishka Research for your glass delamination studies, you’re not just getting a service provider; you’re getting a partner who is committed to your success. We work closely with our clients, providing regular updates and transparent communication throughout the study. Our goal is to build strong and lasting partnerships, delivering personalized services tailored to the unique needs of our clients.

Conclusion

Glass delamination is a complex issue that requires a comprehensive and proactive approach. At Nishka Research, we are dedicated to providing our clients with the knowledge and tools they need to prevent glass delamination and ensure the safety and efficacy of their products. If you’re interested in learning more about our glass delamination studies, we invite you to contact us today. Our team of experts is ready to assist you.

0 Comments