Talc is a mineral that is commonly used in various industries such as cosmetics, pharmaceuticals, and ceramics due to its unique properties such as softness, high thermal resistance, and chemical inertness. However, talc deposits are often found in close proximity to asbestos deposits, and as a result, talc products can become contaminated with asbestos fibers during the mining and milling process. This contamination poses a serious health risk, as asbestos is a carcinogenic mineral that can cause various diseases, including lung cancer and mesothelioma.

Talc is primarily mined in the United States, China, and India, with the largest deposits found in the Appalachian Mountains in the eastern United States. Asbestos, on the other hand, is a naturally occurring mineral that is found in various parts of the world, including the United States, Canada, Russia, and China. Asbestos has been widely used in various industries due to its heat-resistant and insulating properties, but its use has declined due to its harmful health effects.

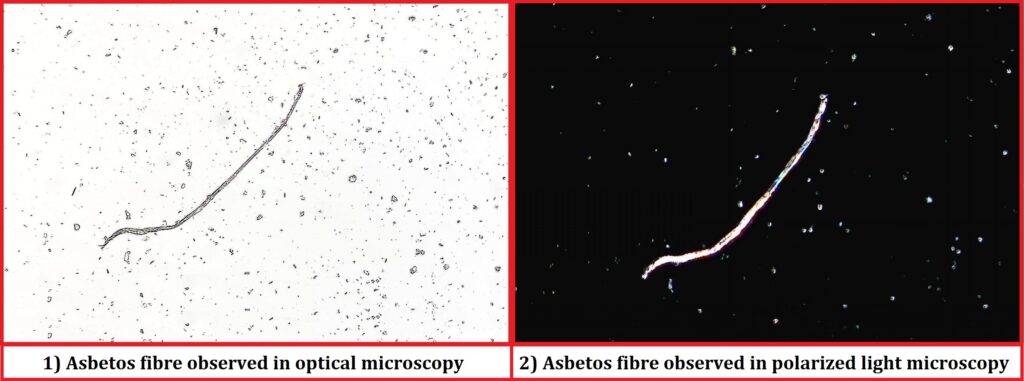

Contamination of talc with asbestos is a serious concern, as it can lead to asbestos exposure and subsequent health risks. Therefore, it is crucial to evaluate talc products for the presence of asbestos to ensure the safety of consumers and workers in industries that use talc. In this blog, we will discuss the qualitative evaluation of asbestos in talc using optical and polarized microscopy, which is a reliable and widely accepted method for detecting asbestos fibers in talc samples.

The use of asbestos in talc is strictly regulated due to its harmful effects on human health. In the United States, the Food and Drug Administration (FDA) regulates talc as a cosmetic ingredient and mandates that all cosmetic-grade talc must be asbestos-free. Additionally, the FDA has set limits on asbestos contamination in talc used in other products such as drugs, medical devices, and food.

In 2019, the FDA released the final report of its testing of talc-containing cosmetic products for asbestos, which found that several products contained asbestos. As a result, the FDA advised consumers to stop using these products and manufacturers to recall them. The report also highlighted the importance of manufacturers testing their talc-containing products for asbestos to ensure they are safe for consumers.

In Europe, the use of asbestos in talc is also regulated by the European Chemicals Agency (ECHA). The ECHA classifies asbestos as a substance of very high concern and has restrictions on its use in products such as cosmetics, toys, and construction materials.

In addition to government regulations, many companies have implemented their own standards and policies regarding asbestos in talc. For example, Johnson & Johnson, one of the largest manufacturers of talc-containing products, announced in 2020 that it would stop selling talc-based baby powder in the United States and Canada due to concerns about asbestos contamination and lawsuits alleging a link between talc and cancer.

Overall, regulatory agencies and companies are taking steps to ensure that talc products are safe for consumers and do not contain asbestos. It is important for manufacturers to comply with regulations and test their products for asbestos to prevent harm to consumers.

In India, the use of asbestos in any form, including talc products, has been banned since 2011 under the Environment (Protection) Act of 1986. The ban was imposed after the World Health Organization (WHO) declared asbestos as a carcinogen and stated that there is no safe level of exposure to asbestos fibers.

The Ministry of Environment, Forest and Climate Change (MoEFCC) has also issued guidelines for the safe handling and disposal of asbestos waste, as well as for the identification and testing of asbestos-containing materials. These guidelines mandate that any material suspected to contain asbestos must be tested in a laboratory certified by the National Accreditation Board for Testing and Calibration Laboratories (NABL).

Additionally, the Bureau of Indian Standards (BIS) has issued standards for asbestos-free talc products, specifying the maximum permissible limits of asbestos fibers in talc. The BIS has also set up a certification scheme for talc products to ensure that they comply with the specified standards.

There are various methods and techniques used for qualitative evaluation of asbestos in talc. These include optical microscopy, polarized light microscopy (PLM), transmission electron microscopy (TEM), and X-ray diffraction (XRD).

Optical microscopy is a commonly used method for qualitative evaluation of asbestos in talc. This technique involves the use of a light microscope to examine the talc sample for the presence of asbestos fibers. The sample is first prepared by mixing it with a mounting medium and then placed on a glass slide for observation. The observer looks for the characteristic features of asbestos fibers, such as a long, thin, and fibrous appearance.

PLM is a more advanced technique than optical microscopy and is often used as a confirmatory test for asbestos in talc. This technique involves the use of polarized light to analyze the physical properties of the asbestos fibers. The talc sample is first treated with a chemical solution to remove any interfering materials, and then placed under a polarizing microscope. Asbestos fibers will appear as bright, elongated structures under polarized light.

Polarized light microscopy (PLM) is a technique commonly used for identifying asbestos fibers in various types of materials. Asbestos fibers have a unique optical property known as birefringence, which allows them to rotate polarized light in a distinctive manner. Birefringence is a property of materials in which light passing through the material is split into two rays, each vibrating in a different plane and with a different refractive index. The difference in refractive index between the two rays causes them to travel at different speeds, which results in a phase shift between the two rays.

Under PLM, a thin section of the material is placed on a microscope stage and viewed under crossed polarizers, where the light waves are at right angles to each other. The fibers in the sample will appear dark against a bright background due to their birefringent nature, while other minerals without birefringence will appear bright.

Asbestos fibers can also be distinguished from other minerals by their characteristic long, thin, and flexible morphology, which gives them a high aspect ratio. Other minerals with similar morphology but lacking birefringence can be ruled out by their different refractive indices and also asbestos fibers have a high degree of birefringence. This property can aid in distinguishing asbestos fibers from other fibers under a microscope, as other fibers typically have a lower degree of birefringence. By observing the degree and pattern of birefringence under polarized light microscopy, trained analysts can often identify asbestos fibers with a high degree of accuracy.

Scanning Electron Microscopy (SEM) is another powerful tool for investigating the presence of asbestos in talc. It involves the use of a focused electron beam to create high-resolution images of the surface of the talc sample, as well as to analyze its elemental composition when it is accompanied with EDS.

SEM can also be used to conduct Energy Dispersive X-ray Spectroscopy (EDS) analysis, which helps to identify the chemical elements present in the talc sample. This technique involves collecting the X-rays emitted by the sample as a result of the electron beam interaction and analyzing them to determine the elemental composition of the sample.

In the case of talc containing asbestos, SEM can be used to identify the characteristic needle-shaped fibers that are indicative of asbestos. These fibers can be further analyzed using EDS to determine their elemental composition and confirm their identity as asbestos.

Overall, SEM is a powerful tool for investigating the presence of asbestos in talc and can provide valuable information on the morphology and elemental composition of the sample. When used in conjunction with other techniques such as FTIR, it can help to provide a more comprehensive understanding of the nature and extent of asbestos contamination in talc.

TEM is a highly sensitive technique for detecting asbestos fibers in talc. This method involves the use of an electron microscope to analyze the talc sample at a high magnification. The talc sample is first prepared by cutting it into thin sections and then placed on a copper grid. The grid is then viewed under the electron microscope, which can identify the characteristic features of asbestos fibers.

XRD is another technique used for qualitative evaluation of asbestos in talc. This technique involves the use of X-rays to analyze the crystal structure of the talc sample. Asbestos fibers have a unique crystal structure that can be identified using XRD. However, XRD cannot differentiate between asbestos and non-asbestos fibers, so it is often used in combination with other techniques.

Fourier Transform Infrared Spectroscopy (FTIR) is a valuable technique that can aid in investigating the presence of asbestos in talc. FTIR is a non-destructive method that measures the interaction of infrared light with a sample. The FTIR spectrum of a sample provides information about the chemical bonds and functional groups present in the sample.

FTIR can be used to differentiate between asbestos and non-asbestos minerals in talc. Non-asbestos minerals such as tremolite, anthophyllite, and actinolite can have similar absorption bands to asbestos minerals. However, the intensity and shape of the absorption bands can differ between asbestos and non-asbestos minerals, allowing for differentiation.

When it comes to the qualitative evaluation of asbestos in talc, it is important to follow best practices in order to ensure accurate and reliable results. Here are some of the best practices for qualitative evaluation of asbestos in talc:

By following these best practices, the qualitative evaluation of asbestos in talc can be performed with confidence and accuracy, ensuring the safety of workers and consumers who may be exposed to talc-containing products.

Qualitative evaluation of asbestos in talc is a complex process that requires a combination of different methods and techniques. While visual identification through optical and polarized microscopy remains the gold standard, FTIR and SEM analysis can provide additional valuable information and support the identification process. It is important to follow best practices and use appropriate safety measures to minimize the risk of exposure to asbestos during sample preparation and analysis.

Overall, the presence of asbestos in talc products is a serious health concern and should not be taken lightly. Asbestos exposure can lead to severe health issues such as lung cancer, mesothelioma, and asbestosis. It is crucial for manufacturers, regulators, and consumers to be vigilant and take necessary precautions to prevent the use and distribution of talc products contaminated with asbestos.

Through proper testing and evaluation, it is possible to ensure that talc products are safe for use and do not pose any health risks. It is the responsibility of all stakeholders to prioritize consumer safety and take necessary measures to prevent the exposure to asbestos.

Are you in need of reliable and accurate testing for asbestos in talc? Nishka Research provides comprehensive testing services using advanced techniques and methods to ensure the safety and compliance of your products. Contact us at [email protected] or +91-7842798518 to discuss your requirements and schedule a consultation. Let us help you ensure the safety of your products and protect the health of your consumers.

Need help or Have a question?

Nishka Research Pvt. Ltd.

Regus Business Center,

4th floor, Gumidelli Commercial Complex,

1-10-39 to 44, Old Airport Road, Begumpet,

Hyderabad-500016

India

Phone : +91 40 29303155

Mobile : +91 7842798518

Left us a star review

I am a PhD scholar from Kaunas University at Lithuania, Europe. I have given a sample to perform SEM analysis of the organic tissue. The results are highly satisfactory and impressive. The service was really excellent, on time( even before the time schedule), consumer friendly. cost to the academic samples are very less comparing with others. Once again thanks to Nishka for providing me the service ontime as I am really in urgency...

A very good lab delivering acurate results. I must also mention about the very cordial staff that they have.

Great work done by nishka research. Thank you so much for your kind Co operation

Submitted the samples for my phd work . Great work and reports submited with 2 days of time . Also the image clarity and all data are clear .

Thank you for your services.. Looking forward for more collaboration with your labs for my future projects..